Cleanroom at CHyN

The usage regulation is currently in discussion by a clean room commission team.

Members of the team are Prof. Wolfgang Hansen (speaker), Prof. Erika Garutti, Prof. Dorota Koziej, Prof. Robert H. Blick, Prof. Henning Moritz, Prof. Wolfgang Hillert, Prof. Guenter Sigl, Dr. Irene Fernandez-Cuesta

For technical information about the clean room please contact:

Thomas Finger, tfinger@chyn.uni-hamburg.de

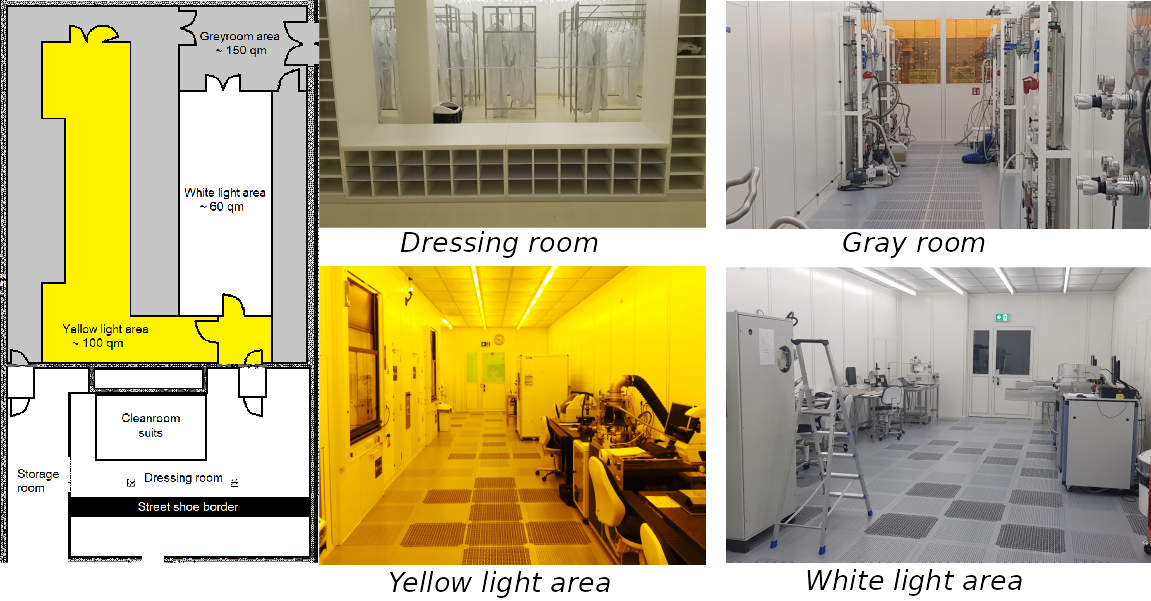

General information

- Construction year 2017

- Cleanroom class ISO 4

- Divided into three areas:

- Yellow light area (~100 m²)

- White light area (~ 60 m²)

- Gray room area (~150 m²)

- Working space for more than 30 users simultaneously

The Cleanroom is divided into three working areas.

The yellow light area is intended for working with photosensitive resists and the cleaning and preparing of samples.

For vapor deposition of metals and etching of samples the white light area is provided.

The last working area is the gray room. It contains all the pumps and gas connections for the devices. The gray room area is mostly used by the technicians for the maintenance of the devices.

In addition to the three working areas of the cleanroom there is also a dressing room, where all cleanroom suits are stored for the users, and also a storage room, where all consumables are stored.

List of Tools

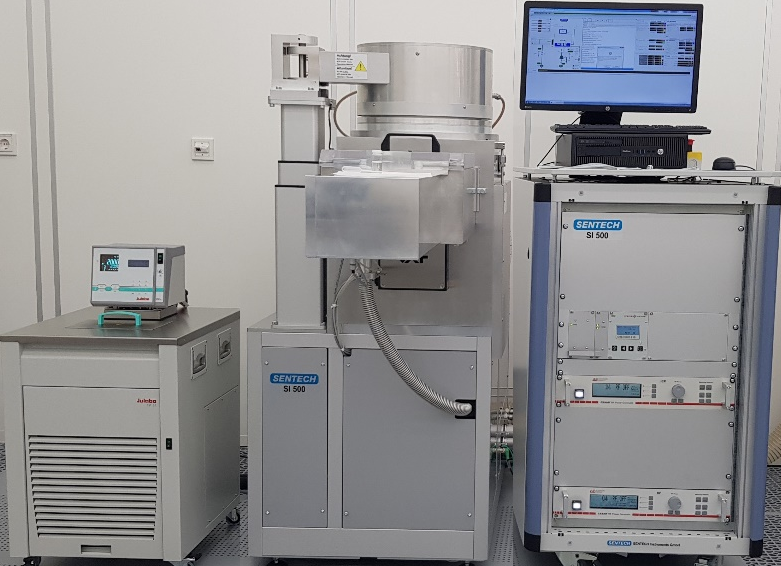

ICP-PECVD

Manufacturer: Sentech

Type: SI 500 D

Construction year 2015

Deposition of SiO2 and Si3N4 with an accuracy of a few nanometers

ICP-RIE (Si)

Manufacturer: Sentech

Type: SI 500

Construction year 2015

Dry etching of Si, SiO2 and Si3N4

Bosch process for deep-RIE available

ICP-RIE (III-V)

Manufacturer: Sentech

Type: SI 500

Construction year 2019

Dry etching for GaAs, InGaAs and AlAs with high selectivity

Physical Vapor Deposition

Manufacturer: Balzers Pfeiffer

Type: PLS 500

Construction year 1995

Thermal and electron beam evaporation of many metals

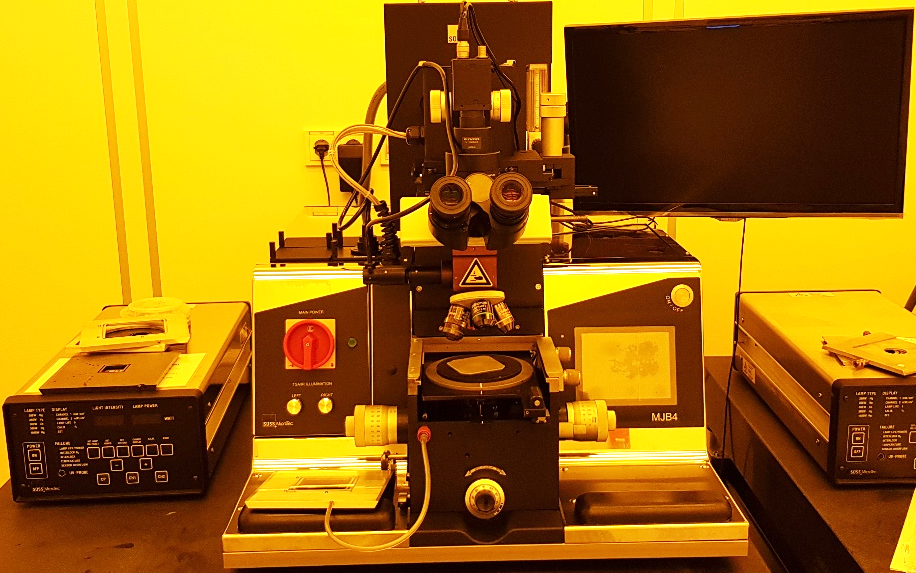

Mask aligner

Manufacturer: Karl Süss

Type: MJB3

Construction year 2005

Contact exposure method

Optical microscope

Reflected light microscope from Leica used for control of the lithography.

Wet bench (4x)

Manufacturer: Arias

Construction year 2017

Integrated overflow basin, ultrasonic basin, spin coater, nitrogen gun and drying oven

General information

Verflüssigungsraten reines Gas:

Ohne LN2 Vorkühlung : 32 L/Std

Mit LN2 Vorkühlung: 56 L/Std

Verflüssigungsraten verunreinigtes Gas:

Ohne LN2 Vorkühlung: 25 L/Std

Mit LN2 Vorkühlung: 45 L/Std

Verflüssigte Menge Helium 2018: ~ 93 000Liter

Flüssigheliumtank: 5000 L

Helium Team

Helium Technician

Alina Trumpjahn

Helium Technician

Gerd Neuber